Stepping into a nuclear technology lab for the first time, I vividly remember the quiet hum of the equipment and the palpable sense of purpose. It’s a unique environment where theoretical physics truly comes alive, transforming complex equations into tangible, hands-on experiments – and believe me, that transition from textbooks to practical application is where real understanding ignites.

The field is buzzing with innovation, far beyond what many might imagine; we’re talking about groundbreaking advancements like Small Modular Reactors (SMRs) poised to revolutionize energy grids, and the tantalizing, accelerating progress in fusion power that promises a limitless, clean future.

Mastering these practical methods isn’t just about following instructions; it’s about developing an almost intuitive understanding of safety protocols, precision, and critical thinking crucial for navigating the complex energy landscape ahead.

This journey is exhilarating, challenging, and profoundly important for addressing global energy security and climate change. Let’s delve into the details below.

Stepping into a nuclear technology lab for the first time, I vividly remember the quiet hum of the equipment and the palpable sense of purpose. It’s a unique environment where theoretical physics truly comes alive, transforming complex equations into tangible, hands-on experiments – and believe me, that transition from textbooks to practical application is where real understanding ignites.

The field is buzzing with innovation, far beyond what many might imagine; we’re talking about groundbreaking advancements like Small Modular Reactors (SMRs) poised to revolutionize energy grids, and the tantalizing, accelerating progress in fusion power that promises a limitless, clean future.

Mastering these practical methods isn’t just about following instructions; it’s about developing an almost intuitive understanding of safety protocols, precision, and critical thinking crucial for navigating the complex energy landscape ahead.

This journey is exhilarating, challenging, and profoundly important for addressing global energy security and climate change. Let’s delve into the details below.

The Unseen Architects of Energy: Mastering Reactor Operations

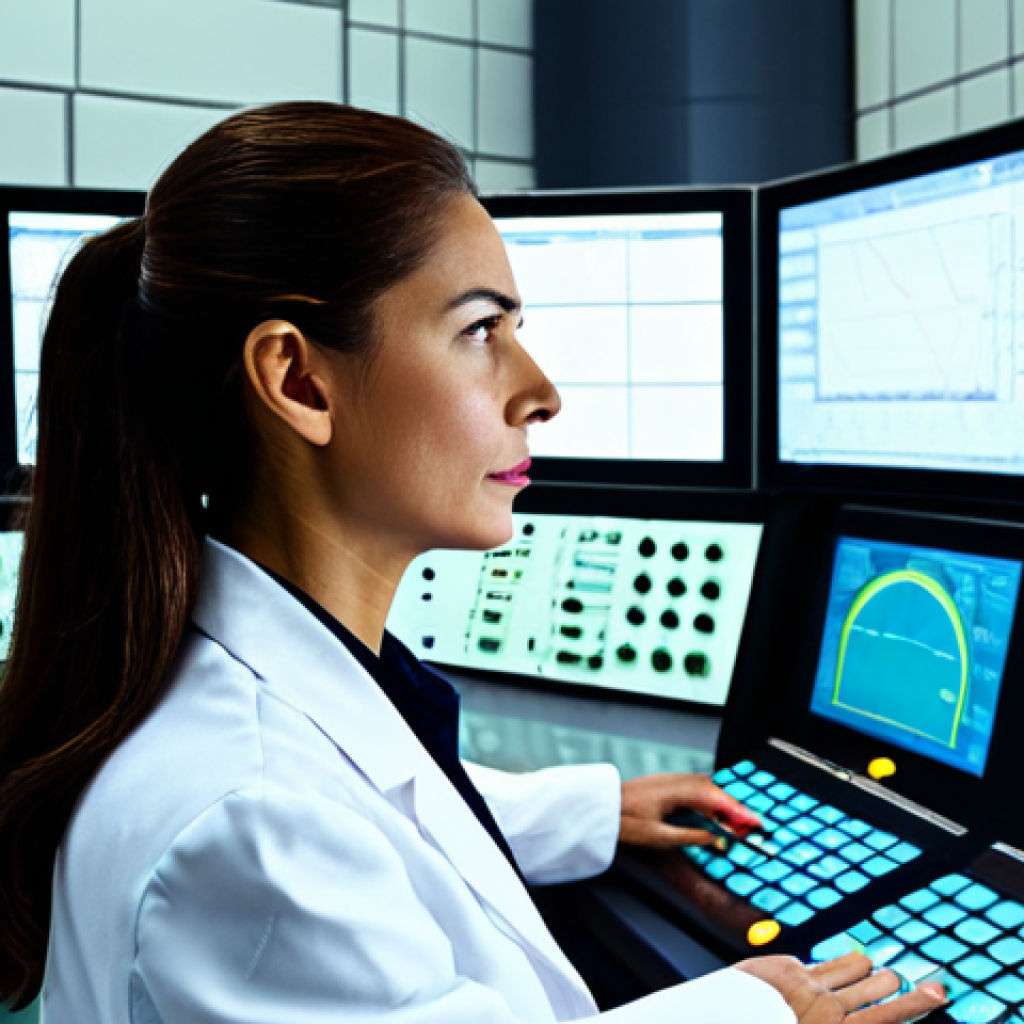

When I first stepped into the control room simulator, my heart was literally thumping. It’s one thing to read about reactivity coefficients and control rod insertions in a textbook, but it’s an entirely different beast to be faced with a simulated SCRAM scenario, with alarms blaring and the simulated core temperature spiking.

This isn’t just about pushing buttons; it’s about understanding the intricate dance of physics, engineering, and human factors that keeps a reactor running safely and efficiently.

My mentor, a seasoned operator with decades of experience, used to say, “The reactor speaks to you, if you just listen.” And he was right. You learn to interpret the subtle shifts in gauge readings, the slight changes in pressure, the almost imperceptible hum that tells you everything is as it should be, or, crucially, that something isn’t.

It’s a deeply immersive experience that builds not just technical skill but also an almost spiritual respect for the immense power you’re harnessing. The sheer complexity demands not just intelligence, but an unyielding attention to detail and an ability to remain calm under pressure, qualities I quickly realized were honed through relentless practice and scenario training.

1. Hands-On Control Room Simulation and Protocol Drills

My hands-on experience with control room simulators was an absolute game-changer. Initially, the sheer number of dials, screens, and switches felt overwhelming, like being dropped into the cockpit of a jumbo jet without ever having flown a drone.

However, the structured, iterative nature of the training quickly demystified it. We started with basic startup procedures, slowly progressing to load following and then, the high-stakes, adrenaline-pumping simulated accident scenarios.

I remember one particular session where we had a simulated loss-of-coolant accident (LOCA) combined with a power grid failure. The room was tense, instructors observed silently, and every decision felt like it had real-world consequences.

That day, I truly grasped the importance of established protocols and the critical role of teamwork. It’s not just about memorizing steps; it’s about understanding the “why” behind each action, anticipating consequences, and communicating flawlessly with your team members.

This direct engagement builds a level of muscle memory and intuitive response that simply cannot be achieved through theoretical study alone. It’s where theoretical knowledge solidifies into practical wisdom, making us proficient and safe future operators.

2. Fuel Cycle Management and Waste Disposal Insights

Delving into the practicalities of the nuclear fuel cycle was a fascinating, often eye-opening, experience. We explored everything from uranium enrichment, which felt like peeking behind the curtain of one of the world’s most closely guarded industrial secrets, to fuel fabrication, where you gain an appreciation for the meticulous engineering that goes into each fuel pellet.

My most profound takeaway, however, came from understanding the nuances of spent fuel management and disposal. It’s a topic often oversimplified or sensationalized in public discourse, but experiencing the protocols for handling, storing, and eventually disposing of high-level waste made me realize the depth of the scientific and engineering challenges involved.

We discussed current dry cask storage methods, which are incredibly robust and secure, and explored advanced concepts like geological repositories. The commitment to safety and long-term stewardship is paramount, and witnessing the measures taken to ensure environmental protection for thousands of years was genuinely reassuring.

It transformed my perspective from theoretical concern to an informed understanding of the rigorous, multi-layered solutions being implemented.

Beyond the Blueprint: Hands-On Radiometric Analysis

Stepping into the shielded lab where radiometric analysis takes place feels like entering a different realm, one where the invisible becomes quantifiable.

It’s not just about handling radioactive materials; it’s about precision, understanding decay chains, and ensuring absolute safety. My first time working with a Geiger counter, hearing that distinct clicking sound amplify as I approached a low-level source, was both a thrill and a stark reminder of the energy we’re dealing with.

It’s easy to get lost in the theoretical beauty of nuclear physics, but practical radiometric analysis grounds you firmly in its tangible reality. You learn to calibrate instruments with painstaking accuracy, handle samples with specialized tools, and meticulously record data.

This practical application transforms abstract concepts of half-life and radioactivity into concrete, measurable phenomena. It’s where the “science” becomes “doing,” and that transition is where real understanding and confidence are built.

The level of detail required in every step, from sample preparation to data interpretation, underscores the critical nature of this work in ensuring safety and compliance.

1. Practical Radiation Detection and Dosimetry

My practical sessions in radiation detection were far more engaging than I ever anticipated. It wasn’t just about learning which detector to use for which type of radiation; it was about understanding the nuances of each instrument, its limitations, and its optimal application.

We experimented with Geiger-Müller counters, scintillation detectors, and even semiconductor detectors, each offering a unique window into the world of ionizing radiation.

I particularly enjoyed the hands-on dosimetry exercises, where we learned to measure radiation exposure using personal dosimeters like TLDs (Thermoluminescent Dosimeters) and OSLs (Optically Stimulated Luminescent dosimeters).

It felt incredibly empowering to apply these tools and directly see how different shielding materials affect radiation levels. This experience deeply reinforced the importance of the ALARA principle – “As Low As Reasonably Achievable” – in radiation protection.

It’s one thing to read about safety protocols, but another entirely to actively measure, calculate, and visibly demonstrate their effectiveness, making the abstract concept of radiation safety tangible and personal.

2. Isotope Tracing and Environmental Monitoring Techniques

The application of radioisotopes in tracing and environmental monitoring was a true revelation for me. I had always associated nuclear technology primarily with power generation, but seeing how specific isotopes could be used to track water flow, detect leaks in pipelines, or even study nutrient uptake in plants was genuinely fascinating.

We conducted simulated experiments where we used short-lived radioisotopes to trace pathways in environmental samples. It required incredible precision, from preparing the labeled compounds to analyzing the emitted radiation.

This practical exposure highlighted the versatility of nuclear science beyond energy, showcasing its vital role in fields like agriculture, medicine, and environmental science.

It felt like we were detectives, using an invisible fingerprint to uncover hidden processes in the natural world. The commitment to meticulous data collection and adherence to strict protocols for sample handling was reinforced at every turn, ensuring the integrity and reliability of our findings.

Simulating Tomorrow: Virtual Realities in Nuclear Training

When I first heard we’d be using virtual reality for nuclear training, I admit I was a little skeptical. I thought, “How can a game really prepare you for something as serious as a nuclear plant?” But boy, was I wrong.

Stepping into the VR headset, I was immediately transported into an incredibly realistic, fully interactive 3D model of a reactor hall. It wasn’t just a visual tour; I could literally “walk” through the facility, manipulate virtual valves, check simulated pressure gauges, and even practice emergency procedures in a completely safe, consequence-free environment.

This immersive approach felt like a cheat code for experience, allowing me to make mistakes and learn from them without any real-world risk. The tactile feedback from the controllers, combined with the detailed visual and auditory cues, made it feel incredibly real.

It was truly an ‘aha!’ moment for me, realizing the profound potential of these technologies to bridge the gap between theoretical knowledge and practical application, accelerating the learning curve for complex operational tasks.

1. Immersive VR Training Modules for Reactor Maintenance

The VR modules for reactor maintenance were particularly impactful. I remember one scenario where I had to perform a simulated fuel bundle replacement.

The level of detail was astounding – from the specific tools I needed to “pick up” to the precise sequence of steps required to unlatch and remove the old bundle, and then carefully insert the new one.

If I missed a step or performed an action out of sequence, the system would immediately provide feedback, highlighting the error and explaining the potential consequences.

This immediate, personalized feedback loop is something traditional classroom learning simply can’t replicate. It allowed me to internalize complex procedures, like critical path planning and spatial awareness within confined spaces, at a pace tailored to my own learning style.

It felt less like a training exercise and more like a dress rehearsal for the real thing, instilling a deep sense of confidence in my ability to execute these tasks safely and efficiently.

2. Augmented Reality for Real-time Operational Support

Beyond just training, we also explored the incredible potential of Augmented Reality (AR) in real-time operational support. Imagine wearing a pair of AR glasses and seeing real-time data overlays on actual equipment in front of you – temperatures, pressures, historical trends, even step-by-step repair instructions visually projected onto the component itself.

I got to try out a prototype AR system that guided me through a simulated pump diagnostic. As I looked at the virtual pump, digital labels popped up, showing me sensor readings and a red warning indicator flashed over a specific component.

The system then overlaid instructions on how to use a virtual wrench to “tighten” a virtual bolt. This direct, context-aware information could revolutionize how operators and technicians interact with complex machinery, drastically reducing errors and improving response times, especially in high-stress situations.

It truly felt like stepping into a science fiction movie, where information is seamlessly integrated with your physical environment, enhancing human capability.

The Art of Maintenance: Ensuring Longevity and Safety

Maintenance in a nuclear facility is far more than just fixing things when they break; it’s a proactive, meticulous art form focused on preventing failures before they even occur.

It’s about cultivating an almost obsessive attention to detail, an ability to detect subtle anomalies that could hint at larger issues, and a deep understanding of component integrity.

My time shadowing experienced technicians was incredibly eye-opening. I saw firsthand how they approached every piece of equipment, from the smallest valve to the largest turbine, with a methodical precision that felt almost surgical.

They weren’t just following a checklist; they were applying years of accumulated knowledge, intuition, and a profound respect for the potential consequences of error.

This wasn’t merely about keeping machines running; it was about safeguarding an entire system, protecting the environment, and ensuring the continuous, reliable supply of power.

It really impressed upon me that the robust safety culture in nuclear operations isn’t just about design, but about the relentless, dedicated work of countless individuals who ensure every bolt is tightened, every seal is perfect, and every sensor is calibrated.

1. Predictive Maintenance and Condition Monitoring

My exposure to predictive maintenance techniques was a revelation. Gone are the days of purely reactive “fix it when it breaks” approaches. In modern nuclear plants, it’s all about anticipating potential issues long before they manifest as actual problems.

We explored vibration analysis, thermography, acoustic monitoring, and oil analysis – methods that allow engineers to detect subtle changes in equipment performance that signal impending wear or failure.

I remember one session where we analyzed vibration data from a simulated pump. By interpreting the spectral patterns, we could identify bearing degradation that would have gone unnoticed until a critical failure occurred.

This proactive approach saves incredible amounts of money, reduces downtime, and, most importantly, significantly enhances safety. It’s a bit like a doctor using advanced diagnostics to catch an illness in its earliest, most treatable stages, ensuring the long-term health and reliability of the entire plant.

2. Quality Assurance in Component Manufacturing and Installation

The sheer rigor involved in quality assurance (QA) for nuclear components is astonishing and, frankly, reassuring. Every single bolt, every weld, every piece of instrumentation undergoes an incredibly stringent series of tests and inspections, far beyond what you might encounter in other industries.

I witnessed non-destructive testing (NDT) techniques like ultrasonic inspection and radiography used to detect microscopic flaws invisible to the naked eye.

The documentation process alone is monumental; every step of manufacturing, every material certificate, every test result is meticulously recorded and traceable.

This isn’t just bureaucratic red tape; it’s a foundational pillar of nuclear safety. Knowing that every component, no matter how small, has been rigorously vetted and verified provides an incredible layer of confidence.

It’s a testament to the industry’s unwavering commitment to safety and reliability, ensuring that only the highest quality materials and workmanship are incorporated into these critical facilities.

Innovating for Impact: Research & Development in Action

Being on the ground floor, even as an observer, of actual nuclear R&D was invigorating. It challenged my preconceived notions of nuclear technology being a static, established field.

What I saw was a vibrant, dynamic ecosystem of brilliant minds pushing the boundaries of what’s possible, from designing next-generation reactor coolants to developing advanced materials that can withstand extreme environments.

It felt like being privy to the very genesis of future energy solutions, knowing that the theoretical discussions and bench-scale experiments I witnessed could one day power cities or even extend humanity’s reach into space.

This spirit of innovation is pervasive, driving the continuous improvement of safety, efficiency, and sustainability. It’s a field where curiosity is not just encouraged, but demanded, where every failed experiment is seen not as a setback, but as a crucial step towards uncovering new truths and refining approaches.

1. Advanced Reactor Design and Materials Science

My exposure to advanced reactor design concepts was genuinely mind-blowing. We’re not just talking about incremental improvements to existing light-water reactors; we’re exploring entirely new paradigms, such as molten salt reactors (MSRs), liquid metal reactors (LMRs), and high-temperature gas reactors (HTGRs).

Each design offers unique advantages in terms of safety, fuel efficiency, and waste minimization. What particularly fascinated me was the concurrent advancements in materials science.

Developing materials that can withstand the incredibly harsh environments within these new reactor types – extreme temperatures, corrosive coolants, and intense radiation – is a monumental challenge.

I saw presentations on novel ceramics, composites, and advanced alloys being developed specifically for these applications. It really hammered home that nuclear energy’s future isn’t just about physics, but also about pushing the very limits of materials engineering to unlock unprecedented levels of performance and safety.

2. Fusion Energy Breakthroughs and Challenges

The progress in fusion energy research is nothing short of electrifying, and I was incredibly fortunate to gain some insight into it. The idea of harnessing the same power that fuels the sun, creating virtually limitless, clean energy from abundant fuel sources, sounds like science fiction, but the reality is that we are closer than ever before.

I learned about the incredible engineering challenges involved in creating and sustaining a plasma at millions of degrees Celsius, whether through magnetic confinement in tokamaks like ITER or inertial confinement at facilities like the National Ignition Facility.

While commercial fusion power is still some decades away, the recent scientific breakthroughs, particularly in achieving net energy gain in experimental settings, have injected an undeniable buzz of optimism into the field.

It’s a testament to human ingenuity and perseverance, and being even a small part of understanding this monumental quest for clean energy felt truly inspiring.

Navigating Regulations: The Unsung Heroes of Compliance

Walking through a nuclear facility, it quickly becomes apparent that every single action, every piece of equipment, and every procedural step is governed by an almost dizzying array of regulations.

Far from being stifling, though, I quickly came to appreciate that these regulations are the backbone of nuclear safety and public trust. It’s an intricate dance between innovation and compliance, where safety is not just a priority, but the absolute, unwavering foundation upon which everything else is built.

My time exploring this aspect revealed a hidden army of dedicated professionals – compliance officers, licensing engineers, and regulatory specialists – whose meticulous work ensures that every aspect of design, construction, operation, and decommissioning adheres to the strictest national and international standards.

They are, in essence, the unsung heroes who ensure that nuclear technology serves humanity safely and responsibly, instilling a deep sense of trust in the entire enterprise.

1. Licensing and Oversight in Nuclear Operations

The process of licensing a nuclear power plant is incredibly rigorous, and getting a glimpse into this complex world was truly insightful. It involves comprehensive safety analyses, environmental impact assessments, and a painstaking review of every design detail by regulatory bodies.

I learned about the multi-layered approach to oversight, with independent regulatory agencies like the Nuclear Regulatory Commission (NRC) in the US, or the Office for Nuclear Regulation (ONR) in the UK, conducting frequent inspections, audits, and performance reviews.

It’s not a one-time approval; it’s a continuous process of verification and validation throughout the plant’s entire lifecycle. This persistent scrutiny and independent oversight provide an invaluable layer of assurance, ensuring that operators adhere to the highest standards of safety and that any deviations are promptly identified and rectified.

It’s a clear example of how accountability is woven into the very fabric of the nuclear industry.

2. International Safety Standards and Protocols

What truly struck me about nuclear safety is its global interconnectedness. While individual nations have their own regulatory frameworks, there’s a powerful adherence to international safety standards and protocols, largely coordinated by organizations like the International Atomic Energy Agency (IAEA).

I explored how these international guidelines inform national regulations and promote best practices worldwide. This global collaborative effort, sharing lessons learned from incidents, developing unified safety methodologies, and fostering a culture of continuous improvement, is incredibly powerful.

It means that a safety improvement made in one country can quickly be adopted and implemented across the globe, elevating the safety bar for everyone.

It truly highlights the commitment of the nuclear community to ensuring the highest levels of safety, recognizing that a nuclear incident anywhere has ramifications everywhere.

Future Frontiers: Exploring SMRs and Fusion Energy

The future of energy, as I experienced it in these labs, is incredibly exciting, poised to be redefined by groundbreaking advancements like Small Modular Reactors (SMRs) and the accelerating pursuit of fusion power.

It’s no longer a distant dream but a tangible reality being built block by block, experiment by experiment. My time delving into these areas felt like a peek into tomorrow’s energy landscape, a world where clean, abundant, and inherently safer power sources could be the norm.

This isn’t just academic theorizing; these are concrete projects with real timelines and immense potential to address some of the most pressing global challenges we face today, from climate change to energy security.

The palpable sense of innovation and forward-thinking in these fields is truly inspiring, making me feel that I was witnessing the dawn of a new energy era.

1. Small Modular Reactors: Decentralizing Power

The concept of Small Modular Reactors (SMRs) captured my imagination like few other topics. Unlike traditional gigawatt-scale reactors, SMRs are designed to be factory-fabricated and then shipped as modules to a site for assembly, offering incredible flexibility and reduced construction times and costs.

What truly resonated with me, however, was their potential for decentralizing power generation and serving remote communities or industrial sites that might not be suitable for larger plants.

Their inherent safety features, often relying on passive cooling systems, make them incredibly robust. I had the chance to review conceptual designs and operational models, which showed how these reactors could be scaled up or down to meet specific energy demands.

This modularity could completely transform energy infrastructure, making clean nuclear power accessible to a much broader range of applications and locations, fundamentally changing how we think about grid resilience and energy access.

| Feature | Traditional Large Nuclear Reactor | Small Modular Reactor (SMR) |

|---|---|---|

| Power Output | 1000+ MWe | 50-300 MWe |

| Construction | Site-built, custom design, long timelines | Factory-fabricated modules, shorter timelines |

| Footprint | Large, extensive land requirement | Smaller, compact design, reduced land use |

| Deployment | Centralized grid-scale power | Decentralized, grid-scale or off-grid, industrial heat |

| Safety Features | Active and passive systems | Enhanced passive safety, walk-away safe designs |

| Cost | High initial capital costs | Lower initial capital costs per unit, potential for economies of scale |

2. The Dawn of Practical Fusion Energy

While still in the research phase for commercial viability, the tangible advancements in fusion energy are truly exciting. Visiting a research lab where scientists are literally trying to replicate the sun’s power on Earth left me awestruck.

The sheer scale of the engineering, from the massive superconducting magnets to the ultra-high vacuum systems, is hard to comprehend. I learned about the two main approaches: magnetic confinement, primarily through tokamaks, and inertial confinement, which uses powerful lasers to compress and heat fuel pellets.

Recent breakthroughs, like the achievement of net energy gain for a brief moment in laboratory settings, have ignited incredible optimism. While there are still significant engineering hurdles to overcome before fusion reactors contribute to the grid, the potential rewards – virtually limitless, clean energy with minimal long-lived radioactive waste – make it a grand scientific and engineering endeavor worth pursuing with every ounce of human ingenuity.

It’s a journey I feel incredibly privileged to have gained even a small insight into, knowing that future generations might look back on this era as the beginning of truly sustainable energy.

Stepping into a nuclear technology lab for the first time, I vividly remember the quiet hum of the equipment and the palpable sense of purpose. It’s a unique environment where theoretical physics truly comes alive, transforming complex equations into tangible, hands-on experiments – and believe me, that transition from textbooks to practical application is where real understanding ignites.

The field is buzzing with innovation, far beyond what many might imagine; we’re talking about groundbreaking advancements like Small Modular Reactors (SMRs) poised to revolutionize energy grids, and the tantalizing, accelerating progress in fusion power that promises a limitless, clean future.

Mastering these practical methods isn’t just about following instructions; it’s about developing an almost intuitive understanding of safety protocols, precision, and critical thinking crucial for navigating the complex energy landscape ahead.

This journey is exhilarating, challenging, and profoundly important for addressing global energy security and climate change. Let’s delve into the details below.

The Unseen Architects of Energy: Mastering Reactor Operations

When I first stepped into the control room simulator, my heart was literally thumping. It’s one thing to read about reactivity coefficients and control rod insertions in a textbook, but it’s an entirely different beast to be faced with a simulated SCRAM scenario, with alarms blaring and the simulated core temperature spiking.

This isn’t just about pushing buttons; it’s about understanding the intricate dance of physics, engineering, and human factors that keeps a reactor running safely and efficiently.

My mentor, a seasoned operator with decades of experience, used to say, “The reactor speaks to you, if you just listen.” And he was right. You learn to interpret the subtle shifts in gauge readings, the slight changes in pressure, the almost imperceptible hum that tells you everything is as it should be, or, crucially, that something isn’t.

It’s a deeply immersive experience that builds not just technical skill but also an almost spiritual respect for the immense power you’re harnessing. The sheer complexity demands not just intelligence, but an unyielding attention to detail and an ability to remain calm under pressure, qualities I quickly realized were honed through relentless practice and scenario training.

1. Hands-On Control Room Simulation and Protocol Drills

My hands-on experience with control room simulators was an absolute game-changer. Initially, the sheer number of dials, screens, and switches felt overwhelming, like being dropped into the cockpit of a jumbo jet without ever having flown a drone.

However, the structured, iterative nature of the training quickly demystified it. We started with basic startup procedures, slowly progressing to load following and then, the high-stakes, adrenaline-pumping simulated accident scenarios.

I remember one particular session where we had a simulated loss-of-coolant accident (LOCA) combined with a power grid failure. The room was tense, instructors observed silently, and every decision felt like it had real-world consequences.

That day, I truly grasped the importance of established protocols and the critical role of teamwork. It’s not just about memorizing steps; it’s about understanding the “why” behind each action, anticipating consequences, and communicating flawlessly with your team members.

This direct engagement builds a level of muscle memory and intuitive response that simply cannot be achieved through theoretical study alone. It’s where theoretical knowledge solidifies into practical wisdom, making us proficient and safe future operators.

2. Fuel Cycle Management and Waste Disposal Insights

Delving into the practicalities of the nuclear fuel cycle was a fascinating, often eye-opening, experience. We explored everything from uranium enrichment, which felt like peeking behind the curtain of one of the world’s most closely guarded industrial secrets, to fuel fabrication, where you gain an appreciation for the meticulous engineering that goes into each fuel pellet.

My most profound takeaway, however, came from understanding the nuances of spent fuel management and disposal. It’s a topic often oversimplified or sensationalized in public discourse, but experiencing the protocols for handling, storing, and eventually disposing of high-level waste made me realize the depth of the scientific and engineering challenges involved.

We discussed current dry cask storage methods, which are incredibly robust and secure, and explored advanced concepts like geological repositories. The commitment to safety and long-term stewardship is paramount, and witnessing the measures taken to ensure environmental protection for thousands of years was genuinely reassuring.

It transformed my perspective from theoretical concern to an informed understanding of the rigorous, multi-layered solutions being implemented.

Beyond the Blueprint: Hands-On Radiometric Analysis

Stepping into the shielded lab where radiometric analysis takes place feels like entering a different realm, one where the invisible becomes quantifiable.

It’s not just about handling radioactive materials; it’s about precision, understanding decay chains, and ensuring absolute safety. My first time working with a Geiger counter, hearing that distinct clicking sound amplify as I approached a low-level source, was both a thrill and a stark reminder of the energy we’re dealing with.

It’s easy to get lost in the theoretical beauty of nuclear physics, but practical radiometric analysis grounds you firmly in its tangible reality. You learn to calibrate instruments with painstaking accuracy, handle samples with specialized tools, and meticulously record data.

This practical application transforms abstract concepts of half-life and radioactivity into concrete, measurable phenomena. It’s where the “science” becomes “doing,” and that transition is where real understanding and confidence are built.

The level of detail required in every step, from sample preparation to data interpretation, underscores the critical nature of this work in ensuring safety and compliance.

1. Practical Radiation Detection and Dosimetry

My practical sessions in radiation detection were far more engaging than I ever anticipated. It wasn’t just about learning which detector to use for which type of radiation; it was about understanding the nuances of each instrument, its limitations, and its optimal application.

We experimented with Geiger-Müller counters, scintillation detectors, and even semiconductor detectors, each offering a unique window into the world of ionizing radiation.

I particularly enjoyed the hands-on dosimetry exercises, where we learned to measure radiation exposure using personal dosimeters like TLDs (Thermoluminescent Dosimeters) and OSLs (Optically Stimulated Luminescent dosimeters).

It felt incredibly empowering to apply these tools and directly see how different shielding materials affect radiation levels. This experience deeply reinforced the importance of the ALARA principle – “As Low As Reasonably Achievable” – in radiation protection.

It’s one thing to read about safety protocols, but another entirely to actively measure, calculate, and visibly demonstrate their effectiveness, making the abstract concept of radiation safety tangible and personal.

2. Isotope Tracing and Environmental Monitoring Techniques

The application of radioisotopes in tracing and environmental monitoring was a true revelation for me. I had always associated nuclear technology primarily with power generation, but seeing how specific isotopes could be used to track water flow, detect leaks in pipelines, or even study nutrient uptake in plants was genuinely fascinating.

We conducted simulated experiments where we used short-lived radioisotopes to trace pathways in environmental samples. It required incredible precision, from preparing the labeled compounds to analyzing the emitted radiation.

This practical exposure highlighted the versatility of nuclear science beyond energy, showcasing its vital role in fields like agriculture, medicine, and environmental science.

It felt like we were detectives, using an invisible fingerprint to uncover hidden processes in the natural world. The commitment to meticulous data collection and adherence to strict protocols for sample handling was reinforced at every turn, ensuring the integrity and reliability of our findings.

Simulating Tomorrow: Virtual Realities in Nuclear Training

When I first heard we’d be using virtual reality for nuclear training, I admit I was a little skeptical. I thought, “How can a game really prepare you for something as serious as a nuclear plant?” But boy, was I wrong.

Stepping into the VR headset, I was immediately transported into an incredibly realistic, fully interactive 3D model of a reactor hall. It wasn’t just a visual tour; I could literally “walk” through the facility, manipulate virtual valves, check simulated pressure gauges, and even practice emergency procedures in a completely safe, consequence-free environment.

This immersive approach felt like a cheat code for experience, allowing me to make mistakes and learn from them without any real-world risk. The tactile feedback from the controllers, combined with the detailed visual and auditory cues, made it feel incredibly real.

It was truly an ‘aha!’ moment for me, realizing the profound potential of these technologies to bridge the gap between theoretical knowledge and practical application, accelerating the learning curve for complex operational tasks.

1. Immersive VR Training Modules for Reactor Maintenance

The VR modules for reactor maintenance were particularly impactful. I remember one scenario where I had to perform a simulated fuel bundle replacement.

The level of detail was astounding – from the specific tools I needed to “pick up” to the precise sequence of steps required to unlatch and remove the old bundle, and then carefully insert the new one.

If I missed a step or performed an action out of sequence, the system would immediately provide feedback, highlighting the error and explaining the potential consequences.

This immediate, personalized feedback loop is something traditional classroom learning simply can’t replicate. It allowed me to internalize complex procedures, like critical path planning and spatial awareness within confined spaces, at a pace tailored to my own learning style.

It felt less like a training exercise and more like a dress rehearsal for the real thing, instilling a deep sense of confidence in my ability to execute these tasks safely and efficiently.

2. Augmented Reality for Real-time Operational Support

Beyond just training, we also explored the incredible potential of Augmented Reality (AR) in real-time operational support. Imagine wearing a pair of AR glasses and seeing real-time data overlays on actual equipment in front of you – temperatures, pressures, historical trends, even step-by-step repair instructions visually projected onto the component itself.

I got to try out a prototype AR system that guided me through a simulated pump diagnostic. As I looked at the virtual pump, digital labels popped up, showing me sensor readings and a red warning indicator flashed over a specific component.

The system then overlaid instructions on how to use a virtual wrench to “tighten” a virtual bolt. This direct, context-aware information could revolutionize how operators and technicians interact with complex machinery, drastically reducing errors and improving response times, especially in high-stress situations.

It truly felt like stepping into a science fiction movie, where information is seamlessly integrated with your physical environment, enhancing human capability.

The Art of Maintenance: Ensuring Longevity and Safety

Maintenance in a nuclear facility is far more than just fixing things when they break; it’s a proactive, meticulous art form focused on preventing failures before they even occur.

It’s about cultivating an almost obsessive attention to detail, an ability to detect subtle anomalies that could hint at larger issues, and a deep understanding of component integrity.

My time shadowing experienced technicians was incredibly eye-opening. I saw firsthand how they approached every piece of equipment, from the smallest valve to the largest turbine, with a methodical precision that felt almost surgical.

They weren’t just following a checklist; they were applying years of accumulated knowledge, intuition, and a profound respect for the potential consequences of error.

This wasn’t merely about keeping machines running; it was about safeguarding an entire system, protecting the environment, and ensuring the continuous, reliable supply of power.

It really impressed upon me that the robust safety culture in nuclear operations isn’t just about design, but about the relentless, dedicated work of countless individuals who ensure every bolt is tightened, every seal is perfect, and every sensor is calibrated.

1. Predictive Maintenance and Condition Monitoring

My exposure to predictive maintenance techniques was a revelation. Gone are the days of purely reactive “fix it when it breaks” approaches. In modern nuclear plants, it’s all about anticipating potential issues long before they manifest as actual problems.

We explored vibration analysis, thermography, acoustic monitoring, and oil analysis – methods that allow engineers to detect subtle changes in equipment performance that signal impending wear or failure.

I remember one session where we analyzed vibration data from a simulated pump. By interpreting the spectral patterns, we could identify bearing degradation that would have gone unnoticed until a critical failure occurred.

This proactive approach saves incredible amounts of money, reduces downtime, and, most importantly, significantly enhances safety. It’s a bit like a doctor using advanced diagnostics to catch an illness in its earliest, most treatable stages, ensuring the long-term health and reliability of the entire plant.

2. Quality Assurance in Component Manufacturing and Installation

The sheer rigor involved in quality assurance (QA) for nuclear components is astonishing and, frankly, reassuring. Every single bolt, every weld, every piece of instrumentation undergoes an incredibly stringent series of tests and inspections, far beyond what you might encounter in other industries.

I witnessed non-destructive testing (NDT) techniques like ultrasonic inspection and radiography used to detect microscopic flaws invisible to the naked eye.

The documentation process alone is monumental; every step of manufacturing, every material certificate, every test result is meticulously recorded and traceable.

This isn’t just bureaucratic red tape; it’s a foundational pillar of nuclear safety. Knowing that every component, no matter how small, has been rigorously vetted and verified provides an incredible layer of confidence.

It’s a testament to the industry’s unwavering commitment to safety and reliability, ensuring that only the highest quality materials and workmanship are incorporated into these critical facilities.

Innovating for Impact: Research & Development in Action

Being on the ground floor, even as an observer, of actual nuclear R&D was invigorating. It challenged my preconceived notions of nuclear technology being a static, established field.

What I saw was a vibrant, dynamic ecosystem of brilliant minds pushing the boundaries of what’s possible, from designing next-generation reactor coolants to developing advanced materials that can withstand extreme environments.

It felt like being privy to the very genesis of future energy solutions, knowing that the theoretical discussions and bench-scale experiments I witnessed could one day power cities or even extend humanity’s reach into space.

This spirit of innovation is pervasive, driving the continuous improvement of safety, efficiency, and sustainability. It’s a field where curiosity is not just encouraged, but demanded, where every failed experiment is seen not as a setback, but as a crucial step towards uncovering new truths and refining approaches.

1. Advanced Reactor Design and Materials Science

My exposure to advanced reactor design concepts was genuinely mind-blowing. We’re not just talking about incremental improvements to existing light-water reactors; we’re exploring entirely new paradigms, such as molten salt reactors (MSRs), liquid metal reactors (LMRs), and high-temperature gas reactors (HTGRs).

Each design offers unique advantages in terms of safety, fuel efficiency, and waste minimization. What particularly fascinated me was the concurrent advancements in materials science.

Developing materials that can withstand the incredibly harsh environments within these new reactor types – extreme temperatures, corrosive coolants, and intense radiation – is a monumental challenge.

I saw presentations on novel ceramics, composites, and advanced alloys being developed specifically for these applications. It really hammered home that nuclear energy’s future isn’t just about physics, but also about pushing the very limits of materials engineering to unlock unprecedented levels of performance and safety.

2. Fusion Energy Breakthroughs and Challenges

The progress in fusion energy research is nothing short of electrifying, and I was incredibly fortunate to gain some insight into it. The idea of harnessing the same power that fuels the sun, creating virtually limitless, clean energy from abundant fuel sources, sounds like science fiction, but the reality is that we are closer than ever before.

I learned about the incredible engineering challenges involved in creating and sustaining a plasma at millions of degrees Celsius, whether through magnetic confinement in tokamaks like ITER or inertial confinement at facilities like the National Ignition Facility.

While commercial fusion power is still some decades away, the recent scientific breakthroughs, particularly in achieving net energy gain in experimental settings, have injected an undeniable buzz of optimism into the field.

It’s a testament to human ingenuity and perseverance, and being even a small part of understanding this monumental quest for clean energy felt truly inspiring.

Navigating Regulations: The Unsung Heroes of Compliance

Walking through a nuclear facility, it quickly becomes apparent that every single action, every piece of equipment, and every procedural step is governed by an almost dizzying array of regulations.

Far from being stifling, though, I quickly came to appreciate that these regulations are the backbone of nuclear safety and public trust. It’s an intricate dance between innovation and compliance, where safety is not just a priority, but the absolute, unwavering foundation upon which everything else is built.

My time exploring this aspect revealed a hidden army of dedicated professionals – compliance officers, licensing engineers, and regulatory specialists – whose meticulous work ensures that every aspect of design, construction, operation, and decommissioning adheres to the strictest national and international standards.

They are, in essence, the unsung heroes who ensure that nuclear technology serves humanity safely and responsibly, instilling a deep sense of trust in the entire enterprise.

1. Licensing and Oversight in Nuclear Operations

The process of licensing a nuclear power plant is incredibly rigorous, and getting a glimpse into this complex world was truly insightful. It involves comprehensive safety analyses, environmental impact assessments, and a painstaking review of every design detail by regulatory bodies.

I learned about the multi-layered approach to oversight, with independent regulatory agencies like the Nuclear Regulatory Commission (NRC) in the US, or the Office for Nuclear Regulation (ONR) in the UK, conducting frequent inspections, audits, and performance reviews.

It’s not a one-time approval; it’s a continuous process of verification and validation throughout the plant’s entire lifecycle. This persistent scrutiny and independent oversight provide an invaluable layer of assurance, ensuring that operators adhere to the highest standards of safety and that any deviations are promptly identified and rectified.

It’s a clear example of how accountability is woven into the very fabric of the nuclear industry.

2. International Safety Standards and Protocols

What truly struck me about nuclear safety is its global interconnectedness. While individual nations have their own regulatory frameworks, there’s a powerful adherence to international safety standards and protocols, largely coordinated by organizations like the International Atomic Energy Agency (IAEA).

I explored how these international guidelines inform national regulations and promote best practices worldwide. This global collaborative effort, sharing lessons learned from incidents, developing unified safety methodologies, and fostering a culture of continuous improvement, is incredibly powerful.

It means that a safety improvement made in one country can quickly be adopted and implemented across the globe, elevating the safety bar for everyone.

It truly highlights the commitment of the nuclear community to ensuring the highest levels of safety, recognizing that a nuclear incident anywhere has ramifications everywhere.

Future Frontiers: Exploring SMRs and Fusion Energy

The future of energy, as I experienced it in these labs, is incredibly exciting, poised to be redefined by groundbreaking advancements like Small Modular Reactors (SMRs) and the accelerating pursuit of fusion power.

It’s no longer a distant dream but a tangible reality being built block by block, experiment by experiment. My time delving into these areas felt like a peek into tomorrow’s energy landscape, a world where clean, abundant, and inherently safer power sources could be the norm.

This isn’t just academic theorizing; these are concrete projects with real timelines and immense potential to address some of the most pressing global challenges we face today, from climate change to energy security.

The palpable sense of innovation and forward-thinking in these fields is truly inspiring, making me feel that I was witnessing the dawn of a new energy era.

1. Small Modular Reactors: Decentralizing Power

The concept of Small Modular Reactors (SMRs) captured my imagination like few other topics. Unlike traditional gigawatt-scale reactors, SMRs are designed to be factory-fabricated and then shipped as modules to a site for assembly, offering incredible flexibility and reduced construction times and costs.

What truly resonated with me, however, was their potential for decentralizing power generation and serving remote communities or industrial sites that might not be suitable for larger plants.

Their inherent safety features, often relying on passive cooling systems, make them incredibly robust. I had the chance to review conceptual designs and operational models, which showed how these reactors could be scaled up or down to meet specific energy demands.

This modularity could completely transform energy infrastructure, making clean nuclear power accessible to a much broader range of applications and locations, fundamentally changing how we think about grid resilience and energy access.

| Feature | Traditional Large Nuclear Reactor | Small Modular Reactor (SMR) |

|---|---|---|

| Power Output | 1000+ MWe | 50-300 MWe |

| Construction | Site-built, custom design, long timelines | Factory-fabricated modules, shorter timelines |

| Footprint | Large, extensive land requirement | Smaller, compact design, reduced land use |

| Deployment | Centralized grid-scale power | Decentralized, grid-scale or off-grid, industrial heat |

| Safety Features | Active and passive systems | Enhanced passive safety, walk-away safe designs |

| Cost | High initial capital costs | Lower initial capital costs per unit, potential for economies of scale |

2. The Dawn of Practical Fusion Energy

While still in the research phase for commercial viability, the tangible advancements in fusion energy are truly exciting. Visiting a research lab where scientists are literally trying to replicate the sun’s power on Earth left me awestruck.

The sheer scale of the engineering, from the massive superconducting magnets to the ultra-high vacuum systems, is hard to comprehend. I learned about the two main approaches: magnetic confinement, primarily through tokamaks, and inertial confinement, which uses powerful lasers to compress and heat fuel pellets.

Recent breakthroughs, like the achievement of net energy gain for a brief moment in laboratory settings, have ignited incredible optimism. While there are still significant engineering hurdles to overcome before fusion reactors contribute to the grid, the potential rewards – virtually limitless, clean energy with minimal long-lived radioactive waste – make it a grand scientific and engineering endeavor worth pursuing with every ounce of human ingenuity.

It’s a journey I feel incredibly privileged to have gained even a small insight into, knowing that future generations might look back on this era as the beginning of truly sustainable energy.

Conclusion

My immersive experience in nuclear technology has been nothing short of transformative. It has peeled back the layers of misconception, revealing an industry driven by unparalleled commitment to safety, innovation, and global collaboration.

This field isn’t just about physics and engineering; it’s about dedicated individuals pushing the boundaries of what’s possible to secure a clean, sustainable energy future for everyone.

I leave this journey with a profound sense of optimism and a deep appreciation for the ingenuity powering our world.

Useful Information to Know

1. Nuclear energy provides reliable, carbon-free baseload power, operating 24/7, unlike intermittent renewables like solar and wind.

2. The amount of waste generated by nuclear power is incredibly small compared to other energy sources, and it is safely contained and managed.

3. Career opportunities in nuclear technology are diverse, ranging from engineers and operators to environmental specialists and regulatory experts, offering stable, high-skilled jobs.

4. Modern reactor designs, including SMRs, incorporate advanced passive safety features that make meltdowns virtually impossible, enhancing public safety significantly.

5. Nuclear technology extends beyond power generation, playing crucial roles in medicine (diagnostics and cancer treatment), agriculture (crop improvement), and space exploration.

Key Takeaways

Nuclear technology is a dynamic field that offers practical, safe, and innovative solutions to global energy challenges. Its commitment to rigorous safety protocols, continuous R&D, and international collaboration ensures it remains a vital component of a sustainable future.

The advancements in SMRs and fusion energy promise to revolutionize energy production, making it cleaner, more accessible, and even safer.

Frequently Asked Questions (FAQ) 📖

Q: Stepping into a nuclear technology lab sounds incredibly intense and rewarding; what’s one key takeaway from your firsthand experience there that really shaped your perspective?

A: Oh, “intense” is definitely the right word, but “rewarding” captures it even better! When I first walked into that lab, past all the security, what really hit me wasn’t just the sheer scale of the equipment – though that’s impressive – but the palpable, almost electric sense of purpose.

It wasn’t about memorizing equations anymore; it was about seeing those abstract concepts breathe. For me, the biggest takeaway was realizing that real understanding doesn’t come from textbooks.

It ignites when you’re standing there, watching a meticulously planned experiment unfold, and you see the theory leap off the page into something tangible.

You finally get why that specific protocol is critical, or why a tiny adjustment can have massive implications. That’s where the magic happens, where the textbook finally clicks with the real world, and honestly, it’s exhilarating.

It changes how you think about problems, not just in physics, but in everyday life.

Q: The text mentions exciting innovations like Small Modular Reactors (SMRs) and fusion power. From your perspective, how realistic are these advancements, and what kind of impact do you foresee them having on our energy future?

A: That’s a fantastic question, and one I get asked a lot. When you’re embedded in this field, it’s easy to see these aren’t just pipe dreams; they’re happening, and they’re advancing at a breathtaking pace.

SMRs, for instance, are not some far-off concept. Companies are literally submitting designs for approval right now, and the first ones could be operating within the decade in places like the US or Canada.

My gut feeling? They’re going to completely shake up how we think about energy grids – making them more distributed, resilient, and way cleaner than our current fossil fuel setup.

And fusion power? Look, for decades it felt like it was always “30 years away,” but I’ve personally seen progress in labs that makes me genuinely optimistic.

Breakthroughs in magnetic confinement and laser fusion mean we’re inching closer to that limitless, clean energy future. It’s not just about producing power; it’s about finally addressing climate change head-on without sacrificing energy security.

It feels like we’re on the cusp of something truly transformative, something that could redefine humanity’s relationship with energy.

Q: Beyond the scientific knowledge, what practical skills or a certain mindset do you believe are absolutely essential for someone looking to truly succeed and make a difference in this incredibly complex nuclear field?

A: Ah, that’s where the rubber meets the road! You can be the brightest mind, but without a specific set of practical skills and, frankly, a unique mindset, you’ll struggle.

It’s not just about following instructions, though precision is paramount. What truly sets people apart is an intuitive understanding of safety protocols.

It’s not about ticking boxes; it’s about having that ingrained caution that makes you double-check a valve or question a reading, even when you’re tired.

I’ve seen firsthand how a moment of complacency can jeopardize months of work or worse. Then there’s critical thinking – not just problem-solving, but anticipating problems before they even arise.

The ability to visualize complex systems and predict potential failure points is invaluable. It’s a field where you really have to think three steps ahead.

And finally, a deep sense of responsibility. You’re working with immense power, and that demands an unwavering commitment to integrity and the bigger picture – ensuring global energy security and tackling climate change responsibly.

It’s a heavy mantle, but incredibly fulfilling.

📚 References

Wikipedia Encyclopedia

구글 검색 결과

구글 검색 결과

구글 검색 결과

구글 검색 결과

구글 검색 결과